.jpg?v=e6b84392)

Quality & Certificate

Quality control of livinbox

In order to ensure livinbox product quality is maintained or improved, we created an environment in which both management and employees strive for perfection. Our factory is certified to ISO 9001, ISO 50001 and ISO 14051. Based on a number of quality management principles including strong customers focus, the motivation and implication of top management the process approach and continual improvement, we follow these criteria as our quality management system.

Total quality control that ensure all products are equipped with the highest standards that products are perfectly competitive in the international market.

1. Raw Material (Incoming Quality Control)

All incoming raw material is carefully inspected for quality and appearance using Vernier calipers or specialist material gauges before storage and use. Rejected material is sent back to the material suppliers.

2. Material Storage (FAI and IPQC)

To avoid quality issues, the first article will be made before mass production, and our experienced production engineer will ensure the mass production viability. Our engineers will inspect every production step. All inspected data are recorded on a quality control sheet till completing whole production.

3. Packaging (FQC)

:Our packaging line is rigorously designed to ensure that each packaged batch of products meets exacting standards. This eliminates the risk of foreign objects, breakages, incorrect labeling, and mis-packaged products.

4. Delivery

After our QC engineers ensure the products meet the customer specifications and ISO-9001 requirements, the goods will be shipped to the customers within lead time.

In-House Testing Facilities

Except for the above processes for standard quality control, our fully integrated manufacturing operations and in-house testing facilities allow our quality control team to inspect products at every stage of production. We also did various tests to ensure our quality is better than others, like loading test, cycle test, RoHs match test, lead test, resistance to acid and so on.

- Thickness gauge from Parton: 1 set

- Plug gauge from KKS: 2 sets

- Pencil gauge from Mitutoyo: 3 sets

- Pencil testers from Patron: 1 set

- Hunterlab colorflex from NR12/ Groundadvance: 1 set

- Tensiometer from ALGOL: 1 set

- Melt flow index tester from Gotech: 1 set

- Tensile testing machine from Come-Tech: 1 set

- Mechanical impact tester from Come-Tech: 1 set

- Impact specimen angle cutting device from Come-Tech: 1 set

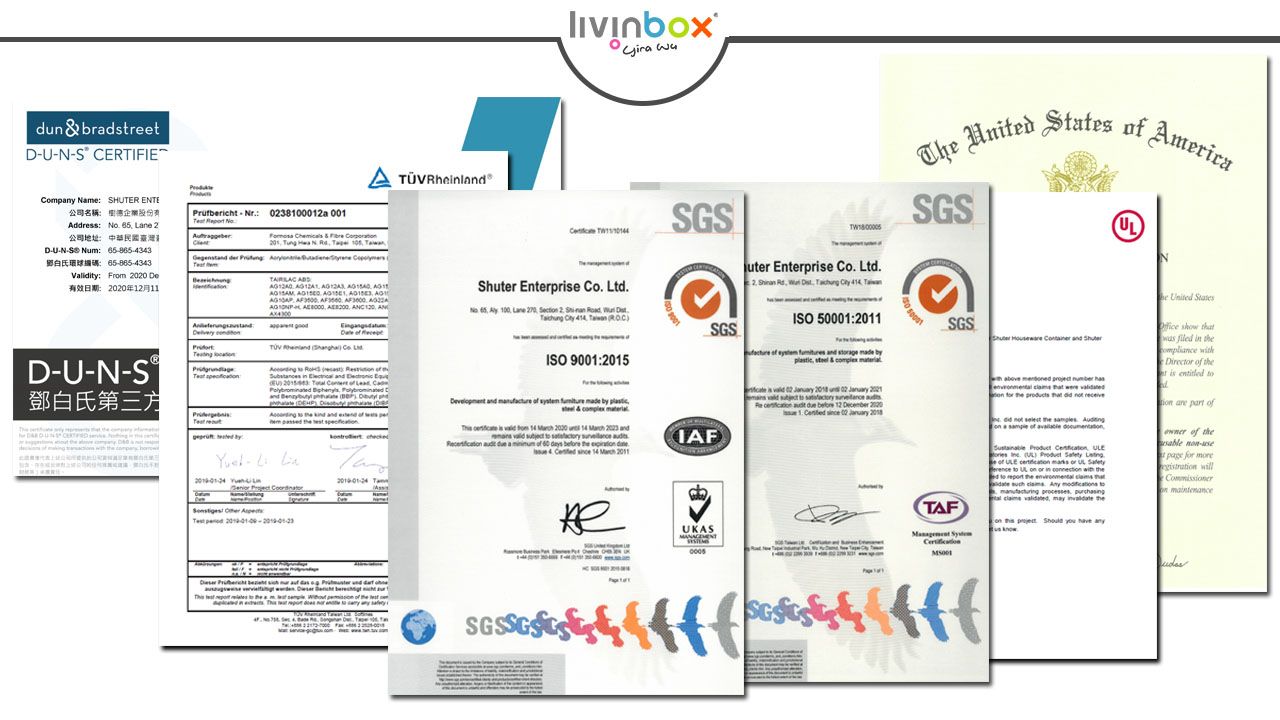

Our Certificates

We are proudly ISO 9001, ISO 50001 and ISO 14051 certified, certified carbon footprint conscious, and have yet to fail a third-party inspection. It is this diligence that keeps our defect rate under 0.01 percent.

ISO 9001 & ISO 50001

Our factory conforms to ISO 9001 to make sure livinbox consistently meet customer needs and enhance customer satisfaction. We increase productivity and efficiency to provide livinbox products with best quality. We also conform to ISO 50001 energy management systems, which enable livinbox production approach in achieving continual improvement of energy performance.

Carbon Footprint Verification

We got Products Carbon Footprint Verification Awards, the desk storage drawers of livinbox series can reduce 7.59g CO2 while producing per item.

Use good mateiral for livinbox products

livinbox products are crafted from virgin PP, PS, and ABS plastics. In order to provide stable and durable storage products, livinbox uses brand-new materials, which are non-toxic, recycled, BPA free, DEHP free and no heavy metals. We ask the quality of materials from the origin for qualified products and input 5% renewable materials with high quality for eco-friendly productions. Based on the concept of earth’ s continuous development, livinbox goals to have all productions no air pollution, no drainage pollution and no noise pollution.

10% energy savings

We are certified by UL Environment Inc. since livinbox adapts MILLAD NX 8000 that enables an average of 10% energy savings for production of clarified PP parts. The plastic parts of livinbox manufactured using 8 to 12% less energy due to clarifier technology.

BPA Free guaranteed

BPA affects your health in more than one. The storage products of livinbox with BPA Free label stand for its safe to drink out of, just enjoy the convenience from livinbox organizers.

DEHP Free guaranteed

We promise livinbox storage products and organizers for children are DEHP free, conform to Toy Safety Standard (CNS 4797) for people safe. Make sure kids are healthy and happy.

Heavy Metal Free guaranteed

The health and environmental issues associated with products use and disposal are a significant concern to both manufacture and consumers. We guarantee all plastic products of livinbox are heavy metals free for safe use.

FDA Approved

The Food and Drug Administration is responsible for protecting the public health by ensuring the safety, efficacy, and security. The material PP of livinbox storage was verified for compliance with American FDA 21 CFR 177.1520. If this is necessary for you, please let us know as soon as you contact us.

Patents of livinbox storage box & organizer

We draw on over half-a-century of expertise to serve our international clients for storage box and organizer and bespoke products. We serve all storage sectors, from office filing systems to household storage. livinbox is trademarked in numerous countries and regions and our products are internationally patented in the U.S., European Union, Taiwan and Japan. We have owned over 30 patents, which also stand for our ability of R&D and high quality.

- Video

.jpg?v=43b5709b)

.jpg?v=8f39f811)

.jpg?v=0a62a4a3)